Industrial IoT

The Industrial IoT will transform companies and countries.

Find out how you can realize a new world of productivity, efficiency, and safety around the world.

The Industrial IoT will transform companies and countries.

Find out how you can realize a new world of productivity, efficiency, and safety around the world.

PEOPLE AND TECHNOLOGY provides key infrastructure solutions for application to the entire range of industrial IoT, aiming to improve business productivity and efficiently manage internal and external environments required for business.

Smart Factories and Industry4.0 are now moving away from slogans and need access strategies through proven solutions that are applied directly in the field.

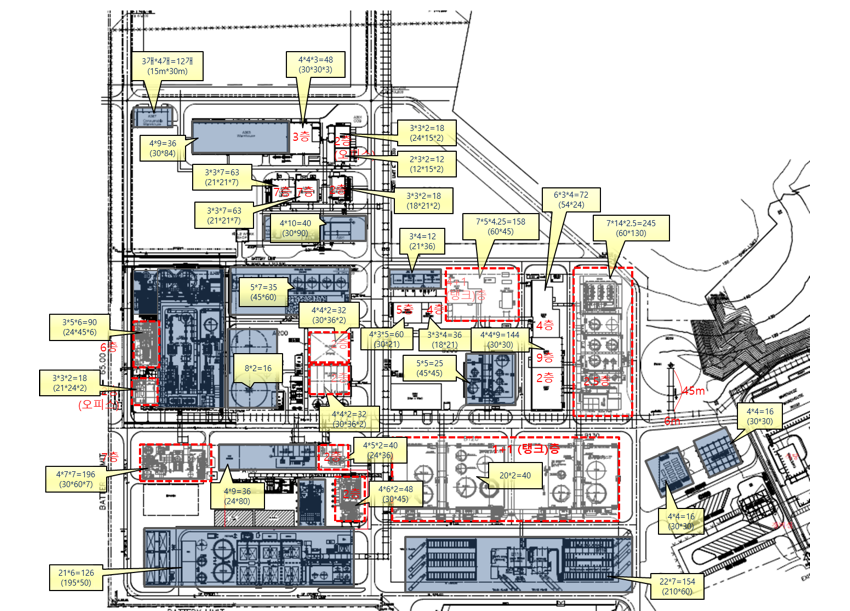

PEOPLE AND TECHNOLOGY IndoorPlus + RTLS solution is based on an IoT solution that incorporates real-life know-how and experience, applying specific services such as “worker safety management”, “asset tracking”, “process efficiency”, and “visitor access control security”.

Are you looking for a solutions partner for your smart factory, Industry 4.0 and your industrial IoT”? PEOPLE AND TECHNOLOGY is your answer!

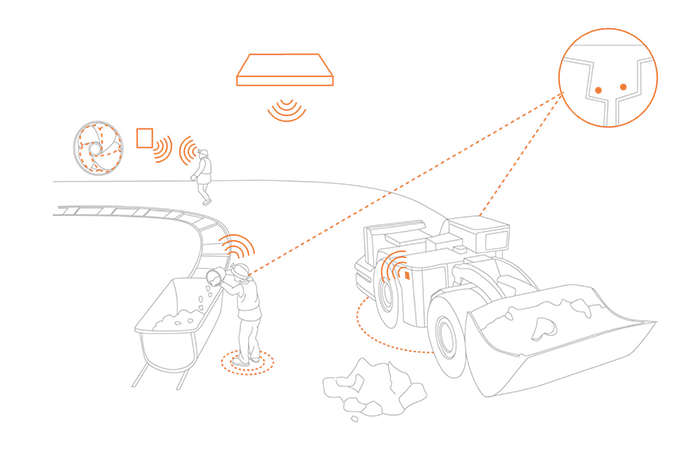

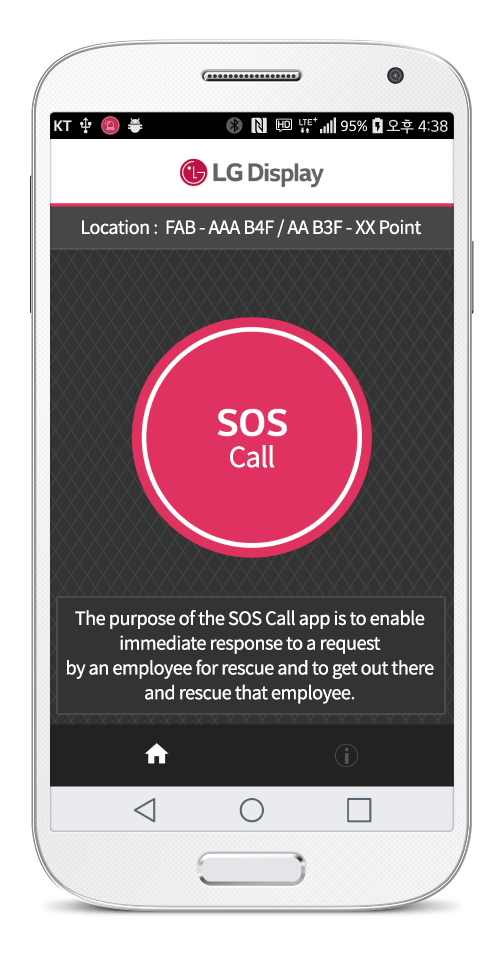

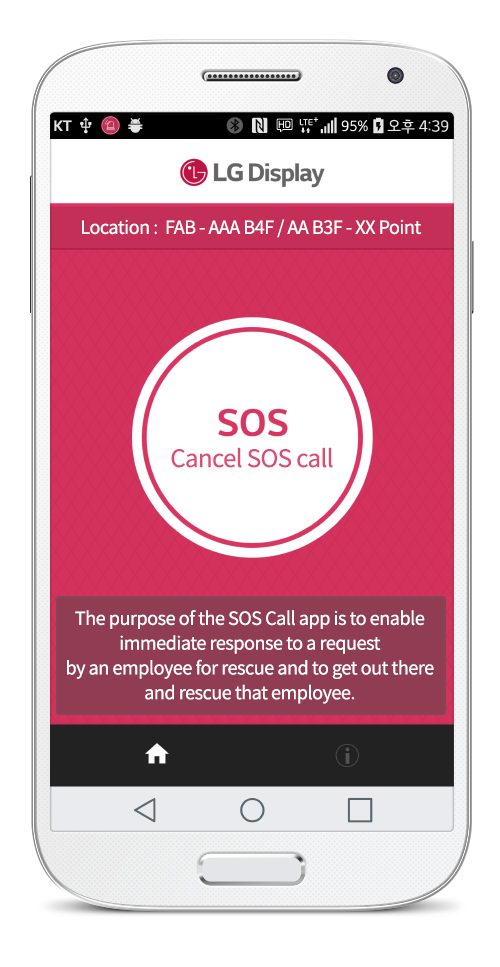

In large workplaces such as factories, safety failures often lead to injury or death because the rescue team cannot arrive in time since production automation makes it difficult to locate workers within the “golden time”.

This affects large manufacturing plants in particular, as such incidents force their expansive production lines to stop while investigations are carried out to find the causes of the accident and to prevent recurrence.

Therefore, a solution that quickly locates workers is crucial as well as to sustain business activities.

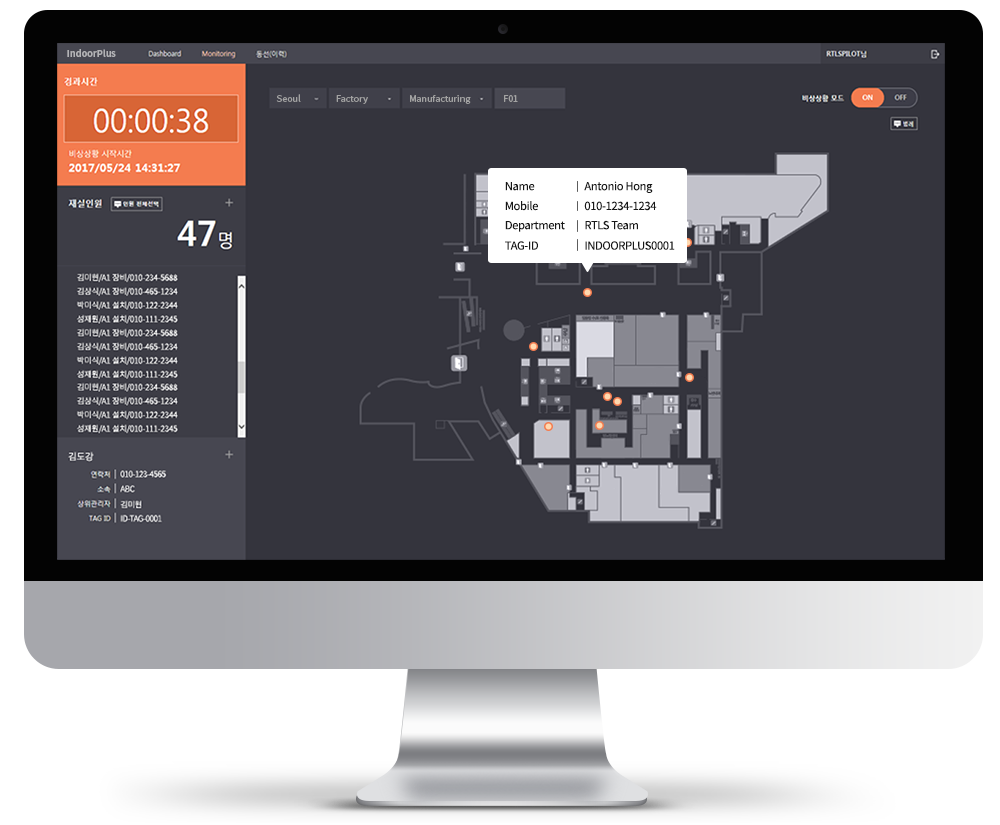

Total number of workers in a specific zone

Time passed after a specific emergency situation

Popup of detailed personal information when a orange dot is selected

private network | and tag configuration | BLE network management server | Tunnel in/out control |

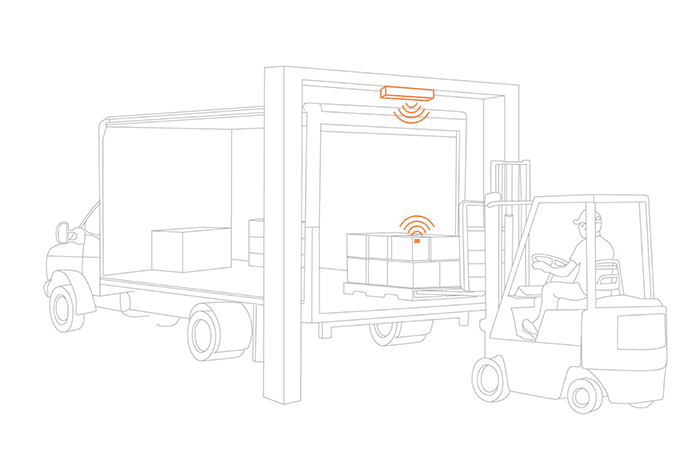

The solution attaches Bluetooth sensors to finished and semi-finished products and even parts, making effective tracking possible throughout the whole production process.

Conventional barcode systems require manual scanning of each object to track its current process.

Such manual tasks often include human error.

This human error degrades the reliability of data generated by the production processes and makes it difficult to manage shipments effectively.

Identifying bottlenecks in each part of each process in real time leads to the ability to correct these problems and help a smart factory dramatically improve productivity.

Broadcasting News

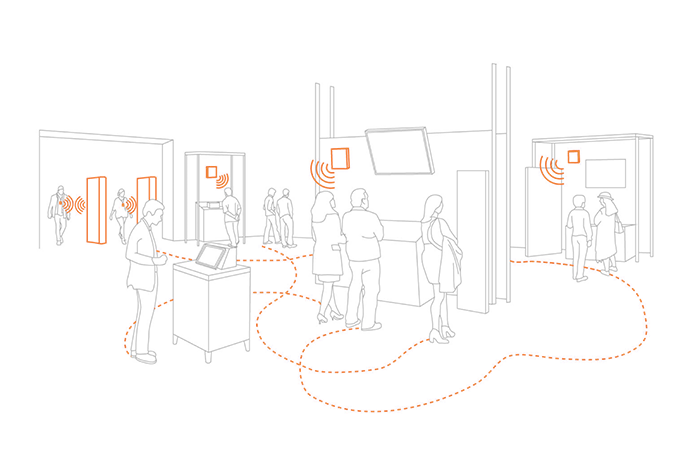

Factory offices and research centers protect key confidential assets and must have high levels of security. The importance of security can never be overemphasized in an environment of stiffening global competition.

In addition to employees, a factory is always busy with vendor staff, visitors, and other people. The importance of location-based security to protect key company assets has increased under such complex environments.

Real-time location tracking reports and monitors anyone entering a restricted zone in real time and enables dispatching of security personnel immediately if needed. CCTV interfacing also allows efficient onsite monitoring.

Moving from point-to-point dot security to line security is a key value.

Pioneering industrial IoT technologies such as digital twining using corporate phones and business tablet devices in private LTE and wireless mobility business environments were introduced in 2017.

Indoor location and sensorization are the key software for these digital twinning systems.

The smart maintenance system tracks precisely (within 2-3 m) the current locations of people inside a factory to enable smart and efficient management of equipment and maintenance work.

The system provides a mobile smart work environment with 3D electronic mapping of facilities and augmented reality (AR) technology.

Tracking current location of workers

Visual Indoor Navigation

Worklist based on current location

Popup guidance on work target and method

Details of work orders in AR

Registration of worklists, status, and findings of each inspector

Work order, progress management and knowledge accumulation

Equipment history, repair, and operation data

Site safety data, alert notices, etc.