I’m looking to improve

with a

We bring value at

all levels of your business

We offer a comprehensive platform with a simple hassle-free integration.

SCROLL DOWN

Enhance Operational Efficiency

Implement real-time IoT asset tracking, automate inventory management and maintenance alerts, and optimize resource allocation based on usage patterns to improve overall productivity.

Optimize Safety and Compliance

Effortlessly identify workflow bottlenecks, track vital signs for individual wellbeing, and monitor critical environmental parameters to ensure safety and compliance.

Enhance Workforce Satisfaction

Reduce staff workload through task automation and remote monitoring, enhance equipment tracking to save time, and improve workflows for a more satisfying work environment.

Strengthen Security and Access Control

Automatically enforce area restrictions with geofencing, receive real-time alerts for unauthorized entries, and ensure personnel safety and compliance through real-time tracking.

Improve Navigation and Facility Management

Help individuals navigate complex facilities with location-based services, provide real-time updates on nearby facilities, and maintain optimal conditions for comfort and safety through adaptive monitoring.

PEOPLE AND TECHNOLOGY ? PEOPLE AND TECHNOLOGY ?

Simple, Cost-effective, Powerful

3 Core Technologies 3 Core Technologies

Whatever your monitoring need is, we have a solution for you.

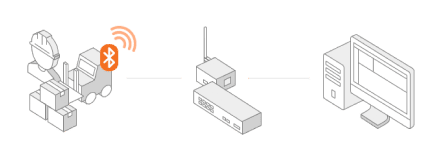

IndoorPlus+ RTLS

Trace everything, in real-time,

on an intuitive interface.

Uses : Worker safety management, Access security, Asset management, Warehouse management, Vehicle tracking.

IndoorPlus+ LBS

Find your way within a facility,

and discover the surroundings.

Uses : Online-to-offline marketing, Indoor navigation, Indoor positioning, Location-based personalization target content delivery

IndoorPlus+ Smart Sensing

Monitor the status of your devices

and environmental prameters.

Uses : Cold-chain devices for medical use, Patient biometric monitoring, Toxic gas detection, Etc.

Customer Success

with Our Platform

Hundreds of Hospitals and leading companies from all industries use our Platform. Find out why. Check our site deployments stories to learn what made PEOPLE AND TECHNOLOGY an ideal choice for our customers businesses, and how we can become yours.

Hundreds of Hospitals and leading companies from all industries use our Platform. Find out why. Check our site deployments stories to learn what made PEOPLE AND TECHNOLOGY an ideal choice for our customers businesses, and how we can become yours.

Experience the transformative power of AI-driven digital transformation.

Customers & Partners

The number of clients using our

IndoorPlus+ solutions

100 +

Total accumulated square meters monitored with

IndoorPlus+ solutions

9,613,268 ㎡

Total number of BLE tags provided

to customers

119,382 * As of April, 2020

_9179b.png)