Driving the Convergence of Smart Factories, Industry 4.0, and RTLS

- AuthorElodie

- DateDec 18, 2024

- Views1068

In 2017, People and Technology has seen a significant rise in inquiries about applying Real-Time Location Systems (RTLS) in conjunction with Smart Factories and Industry 4.0 initiatives. We’ve successfully conducted Proof of Concept (PoC) projects at several sites and are currently negotiating concrete deployments.

Through on-site factory assessments and PoC implementations, we’ve witnessed how RTLS can revolutionize manufacturing by improving productivity, safety, and operational accuracy. Below are some case studies showcasing the practical application of RTLS in smart factory environments.

Case Studies of RTLS in Smart Factories

1. Worker Safety Management – LG Display

Project Duration: December 2016 – January 2017

Objective: Enhanced worker safety in a highly automated factory environment.

At LG Display, one of the world’s largest factories, most production processes are automated, making it difficult to pinpoint the locations of on-site workers. Due to security protocols, workers cannot carry communication devices like smartphones, further complicating their tracking.

In emergencies, accurately identifying the location of workers is crucial for swift response within the golden hour. RTLS emerged as an essential component of worker safety in smart factories, enabling real-time worker tracking and ensuring their security during unexpected incidents.

2. Improving Yield and Rapid Worker Deployment – Hanwha Q CELLS

Project Duration: February 2016

Objective: Enhance solar wafer and module production efficiency.

At Hanwha Q CELLS’ factory in Eumseong, Chungcheongbuk-do, maintaining high yield rates is critical to competitiveness. Using IndoorPlus+ RTLS integrated with smart sensors, we implemented a PoC to monitor environmental conditions like temperature and humidity at each production line.

Key steps included:

- Sensor Monitoring: Attaching BLE sensor beacons to monitor environmental conditions and collecting real-time data for pattern analysis.

- Worker Deployment: In case of deviations from optimal conditions, RTLS automatically directs the nearest quality control worker to investigate and resolve issues promptly.

This approach significantly reduced response times to production issues, contributing to higher yields and improved overall productivity.

3. Automated Needs Time Measurement – OOO Defense Manufacturer

Project Duration: Ongoing discussions following factory assessment in early 2017

Objective: Automate process duration tracking for improved production planning.

During a visit to a leading domestic defense manufacturer, we identified a key challenge: measuring the Needs Time (duration for each process) accurately.

Currently, workers manually scan barcodes at the start and end of each process. However, this manual input often leads to delays or inaccuracies, making it difficult to pinpoint bottlenecks or optimize processes.

Using RTLS, we proposed an automated solution:

- BLE Tags on Materials: Attaching BLE tags to raw materials and containers.

- Entry and Exit Points: Tracking when materials enter and exit specific process points to automatically calculate Needs Time.

This automation enables real-time insights into process durations and bottlenecks, forming the foundation for optimizing production efficiency. Following our presentation, the manufacturer is actively reviewing budgets and planning a PoC.

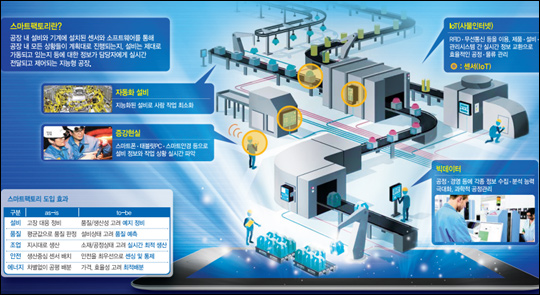

The Role of RTLS in Smart Factories and Industry 4.0

RTLS is emerging as a transformative technology in smart factories, addressing critical areas such as:

- Worker Safety: Real-time tracking to enhance safety protocols in large-scale automated environments.

- Production Efficiency: Sensor integration for environmental monitoring and rapid issue resolution.

- Process Optimization: Automated tracking of process durations to identify and address bottlenecks.

By seamlessly connecting people, machines, and data, RTLS embodies the principles of Industry 4.0, driving smarter, more connected, and efficient industrial environments.

People and Technology remains committed to helping industries realize the full potential of RTLS and IoT solutions. With each successful project, we continue to lead the way in shaping the future of smart factories and Industry 4.0.